Battling grass disease, getting good results with LED-technology and striving for sustainability. The grounds team of VfL Wolfsburg gives an insight into their work and the cooperation with turf specialist SGL system.

The grounds team of VfL Wolfsburg wants to win the Bundesliga best pitch competition.

Image: SGL

SGL system spoke with Peter Sauer, sitting in his office at the Volkswagen Arena, talking about his grounds team, their challenges, the benefits of working with LED-technology and his take on data versus a groundsman’s gut feeling.

And what about those nerves before a home game in one of the world’s most viewed football leagues?

“Everybody is just excited now the season has finally started. We are relaxed, because we’re ready. In the last couple of days before the game, it’s all about details. We mow the pitch one last time, apply fertilizer and something to get a better colour. Then all what’s left is to paint the lines on the pitch and we’re ready for gameday. Earlier we had a last look at the data, regarding the hardness of the pitch, but that looks fine. For us, there is no reason to be nervous. Now it’s up to the team to perform and get the win.”

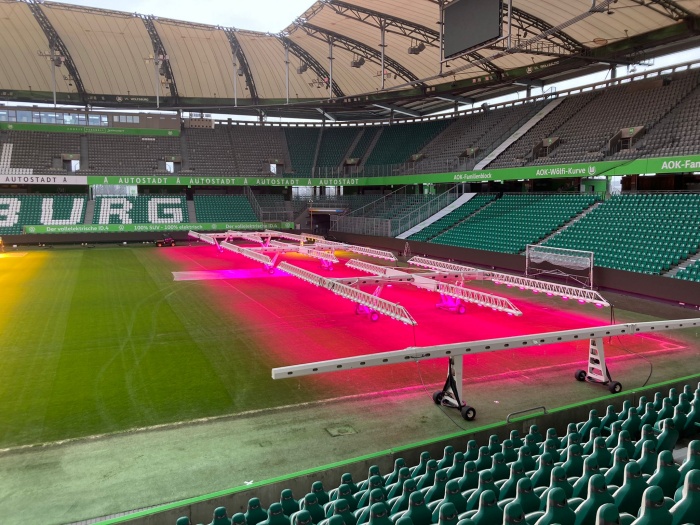

The three LED440’s on the south end of the pitch.

Image: SGL

“LED? It’s like driving a Mercedes or a Porsche.”

Leave it up to a German to make a comparison with automobiles. The independent control of heat and light radiation makes LED-technology ideally suited for high temperature summers. With temperatures currently rising up to 37 degrees Celsius in Germany, heat radiation is not necessary and can be switched off during those hot summer days. This offers the possibility to start the lighting season early and save up on energy.

“This year we started using our LED-units mid-July. Mainly in the shaded areas. Based on the SGL advice we get, we turn them on for 8 to 10 hours a day. You can see a big difference already. We get double rates of clippings in the LED area, as compared with the areas adjacent to the LED treated areas. We used to have spots where there was no grass whatsoever. Now we seed it, water it and put on the LED-units to grow the grass. The individual control of heat and light makes it possible to even use the unit in July, when we already need the light but not the temperature. That’s why we love working with LED. I’m confident that in those shaded areas this season we will have a good root system and good playing conditions without any issues.

Recently we integrated the LED440 units into our pitch management strategy and is has been a joy. It’s like driving a Mercedes or a Porsche. My team loves working with the units and if it was up to us, we would switch to LED completely, as fast as we can. We believe we get the best possible growth with LED. So the agronomical benefits were the number one reason for us to integrate LED-technology.”

Wolfsburg carrying their weight in the strive for sustainability

With sustainability high on the global agenda, more and more clubs come to realize that they have a role to play in the transition towards a more sustainable industry. A responsibility VfL Wolfsburg doesn’t shy away from.

“Sustainability is an important topic in Germany. Across the country, lights in parking lots and in big buildings like offices are being turned off when they are not used. At Wolfsburg we feel we need to play our part and switch of computers and lights whenever we can. Sometimes, when we have the LED-units out on the pitch it may seem like we’re not listening. But the pitch is where we make the money and therefore we need to invest in technology to make it the best surface possible. We’re continuously challenging ourselves to do that in the most eco-friendly way possible. LED helps us to contribute to the club’s sustainability goals and we can save up on energy costs simultaneously. We use less power, especially during the summer, when we don’t need to add heat radiation. We try to postpone the use of heat radiation for as long as possible. Hopefully we won’t need it until November, but we’ll have to see how it goes.”

Plant friendly grass disease treatment

Although summer temperatures create a nice working environment, the hot and humid weather also brings a challenge Peter Sauer has had to face: grass diseases. Although a serious issue, there are eco-friendly measures you can take to prevent or treat infections. The use of chemicals is not something Peter is fond off, he rather treats his pitch with UV-C radiation.

Front view of the LED440.

Image: SGL

We try to avoid using chemicals at all cost. Because once we start with it, chances are we’ll have to use it more frequently. You can compare it with when you’re sick yourself. You try to avoid the use of medicine as much as possible. The same applies for the pitch; the use of the plant friendly UVC180 keeps the pitch healthy in a sustainable way. We hope to stay clean for the rest of the season. Let’s knock on wood.”

High temperatures combined with humidity are conditions where grass diseases thrive in. An infected pitch can cause serious damage to the quality of the grass, not to mention the health of the players. Preventing a grass disease outbreak starts with identifying the type of grass disease you’re dealing with. From there you can run an effective grass disease treatment strategy.

Data, experience and a groundsman’s gut feeling

The strive for sustainability is also reflected in Peter Sauer’s data driven way of working. Data monitoring tools are essential and provide groundsmen with valuable pitch information, such as humidity and air temperature, but also underground values like soil moisture and salinity. Of course, a groundsman’s gut feeling can be a good indicator to steer on, but data monitoring helps groundsmen back up that gut feeling and make objective and substantiated decisions.

“With data we can say ‘here are the numbers, this is why we decided to use the LED-units’. We recently invested in the TurfPods. We can use the TurfPods in different locations of the pitch so we get a clear view on what’s happening above, but also under the pitch. It particularly helps us to monitor differences across the surface and act on it.

Data helps me verify what I see and feel as a groundsman. I don’t steer just on data or just on a gut feeling, the combination of data, gut feeling and experience is eventually what I base my decisions on. And those three should be in balance. The TurfPods contribute to our sustainability goals. With the data and the SGL calculations we can easily see how much light we need and not overdo it. That way we hope to save a couple of hours of light per week.”

Besides data and his groundsman’s gut feeling, the feedback Peter Sauer gets from the players is also highly regarded. After all, they are the once actually using the pitch.

“I speak with the players frequently and we have a good relationship with the team. They give us feedback on how the pitch feels and that’s input we take into account.”

Aiming for the top with top quality tools

Where Peter Sauer and his grounds team finished 3rd in the DFL Pitch of the Year-Award, VfL Wolfsburg ended the 2021/2022 season in 12th place. Both the players and the grounds team aim for a spot higher up the table.

“Last season we started with a pretty good pitch, but then we hit a down. We’re still looking back what the issue was exactly. Fact is that we had to deal with a busy schedule. We had games in December, we played in the Champions League and at times the team practiced on the stadium pitch. In seven days we had five uses. That was tough for the pitch, but with the help of the lighting units we managed to recover during the winter break. At the end of the season we got voted third in the Bundesliga best pitch competition, so we can say we’ve done okay. We’ve got good support from the sports management team and we’re equipped with top quality tools. So for us, ‘okay’ is not good enough. VfL Wolfsburg is a great club with outstanding facilities. The team is great and I love working with them. With the tools we have and the team putting in the effort, this season we’re aiming for that number one spot.”

(STADIAWORLD, 16.08.2022)

Homepage: SGL system